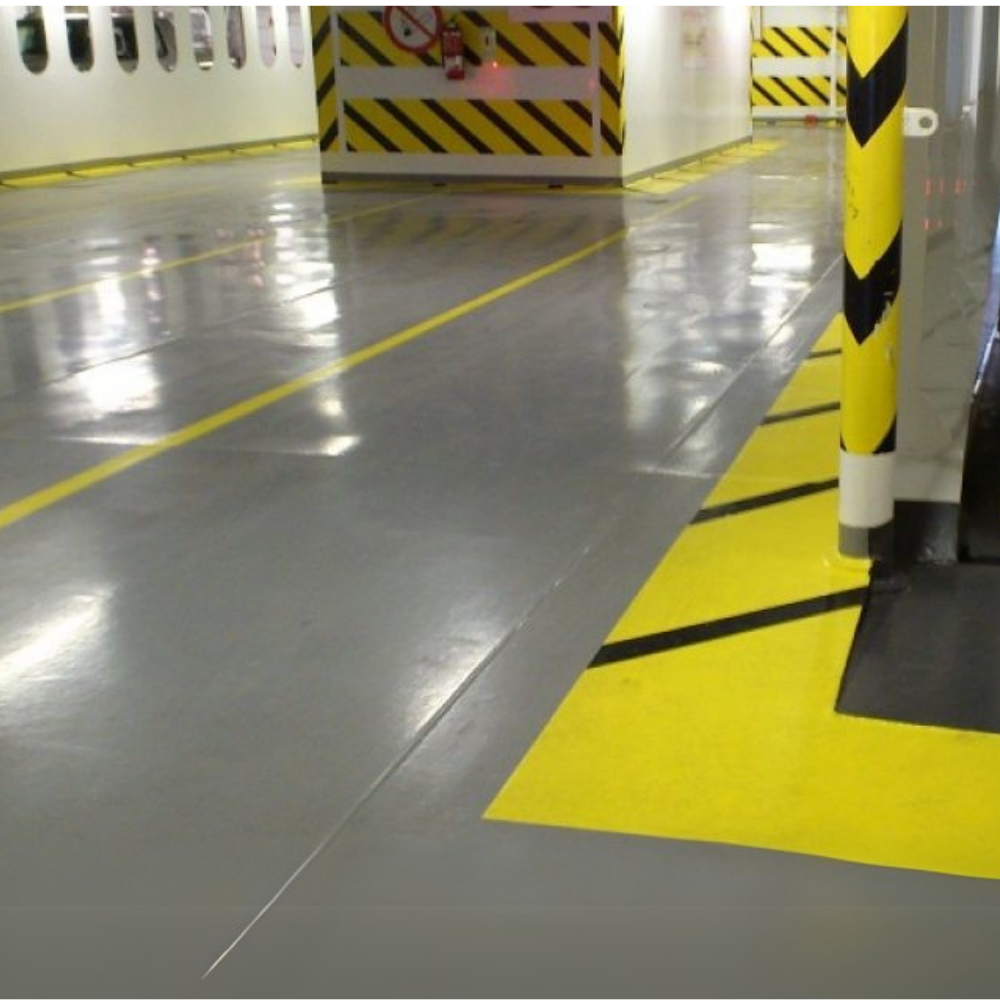

Polyurethane Industrial Flooring

Polyurethane industrial flooring is a durable solution specifically designed for factories, warehouses, production facilities, parking lots, food enterprises, hospitals, and industrial areas exposed to heavy loads. With its chemical resistance, non-slip surface, and high impact strength, it offers long-lasting performance with minimal maintenance.

At Globsan, we provide durable, long-lasting, and high-performance polyurethane industrial flooring for heavy industry and commercial facilities!

Types of Polyurethane Industrial Flooring

- Heavy-Duty and Chemical-Resistant Polyurethane Flooring: Ideal for industrial facilities, production areas, and factories.

- Chemical and Heat-Resistant Polyurethane Coating: High-resistance coating used in the chemical industry, laboratories, and pharmaceutical production facilities.

- Wear and Impact-Resistant Polyurethane Flooring: Suitable for warehouses with heavy forklift and load traffic.

- Non-Slip Polyurethane Coating: Safe solutions for parking lots, airports, and high-footfall commercial spaces.

- Food and Hygienic Industrial Flooring: Antibacterial and hygienic coating for food processing facilities, cold storage areas, and hospitals.

- Flexible and High Shock Absorption Polyurethane Flooring: Impact-resistant, ideal for gyms, logistics centers, and shopping malls.

We offer polyurethane flooring solutions tailored to the needs of every industrial space!

Advantages of Polyurethane Industrial Flooring

- Resistant to Heavy Loads and Impact: Long-lasting flooring suitable for forklifts, heavy machinery, and high traffic.

- Chemical and Liquid Resistance: Superior protection against acids, oils, detergents, and chemical solvents.

- Non-Slip and Safe Surface: Prevents slipping in both wet and dry areas.

- Antibacterial and Hygienic: Ideal for food production, pharmaceutical, and healthcare facilities.

- Temperature-Resistant: Long-lasting use in cold storage and high-temperature environments.

- Easy Cleaning and Low Maintenance: Smooth, impermeable surface for hygienic and easy cleaning.

- Aesthetic and Professional Look: Modern and stylish designs enhance the professional appearance of workplaces

At Globsan, we deliver high-quality industrial flooring solutions using the best materials!

Polyurethane Industrial Flooring Construction Stages

Globsan’s expert teams apply the highest quality standards to ensure that polyurethane industrial flooring is durable, long-lasting, and safe.

1. Site Survey and Surface Analysis

- Measurements of the area to be coated are taken, and the project is prepared.

- The condition of the existing floor is assessed, and necessary repairs are planned.

- The most suitable type of polyurethane coating is selected based on chemical and physical conditions.

Surface preparation is crucial for achieving a durable and reliable industrial flooring system.

2. Surface Preparation and Primer Application

- The existing surface (concrete/asphalt) is cleaned of oil, dirt, and moisture.

- Cracks, holes, and irregularities are repaired with special filling materials.

- A polyurethane-based primer is applied to create a strong bond between the coating and the surface.

The primer ensures the polyurethane coating adheres perfectly to the floor.

3. Polyurethane Flexible Base Layer Application

- The first polyurethane layer is applied to provide impact absorption and flexibility.

- This layer offers extra protection, especially in areas exposed to heavy loads and high traffic.

- The surface is left to cure for the specified period after application.

The base layer enhances the durability of the flooring, ensuring long-lasting performance.

4. Polyurethane Coating and Colored Top Layer Application

- A polyurethane-based coating is applied to the surface for maximum durability.

- A special top layer is added to resist chemical and physical impacts.

- Desired colors and patterns are applied for aesthetic appeal.

The top layer is specially formulated to provide long-term durability in industrial environments.

5. Line and Section Marking (Optional)

- Lines and markings are applied for guidance in warehouses, factories, and parking areas.

- Safety zones, pedestrian crossings, and vehicle routes are marked to create safe areas.

- Long-lasting epoxy or polyurethane-based paints are used for line marking.

Proper floor markings are essential for maintaining traffic order in factories and warehouses.

6. Final Inspections and Delivery

- The coated surface is left to cure for the specified period.

- The floor is inspected, and necessary corrections are made.

- Durability tests are completed before opening the area for use.

At Globsan, we guarantee quality in every project, delivering flawless polyurethane industrial flooring!

Application Areas of Polyurethane Industrial Flooring

- Factories and Production Facilities: Resistant to chemicals, impacts, and heavy loads.

- Logistics and Warehouse Areas: High-strength flooring suitable for forklifts and heavy traffic.

- Parking Lots and Commercial Areas: Wear-resistant, non-slip surface coating.

- Hospitals and Hygienic Areas: Antibacterial and easy-to-clean surfaces.

- Food Production Facilities: Non-slip, liquid-proof coating that meets hygiene standards.

- Laboratories and Chemical Industry: Special coating systems with high chemical resistance.

At Globsan, we offer the best polyurethane flooring solutions for industrial environments!

Contact us and bring your professional industrial flooring projects to life!