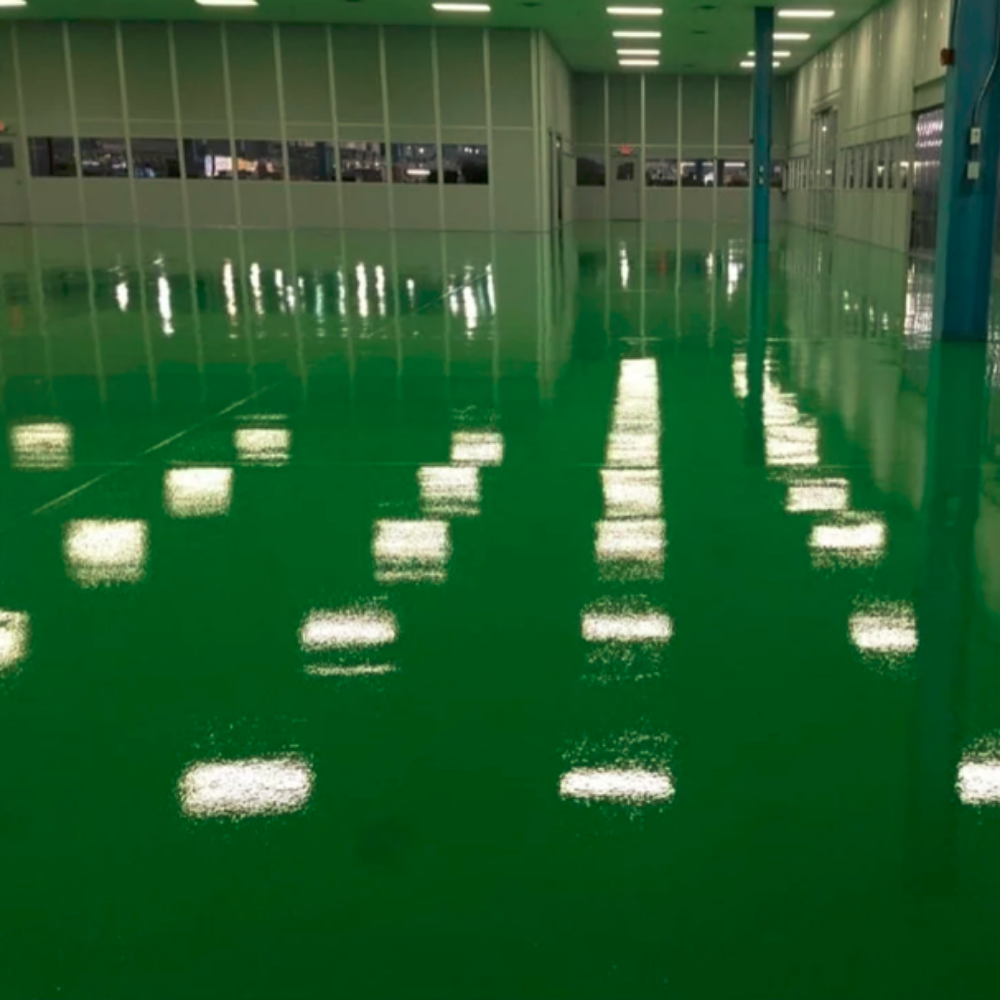

Epoxy Industrial Flooring

Epoxy industrial flooring provides durability, chemical resistance, and an aesthetic appearance for factories, warehouses, parking garages, production facilities, laboratories, and food processing plants.

Its high-strength structure makes it suitable for heavy loads, high-traffic areas, and demanding working conditions, offering a non-slip and hygienic surface.

At Globsan, we deliver professional epoxy flooring solutions tailored for industrial environments!

Types of Epoxy Industrial Flooring

- Heavy-Duty Epoxy Flooring → Ideal for factories and warehouses with heavy traffic.

- Hygienic Epoxy Coating → Antibacterial flooring for food production facilities, laboratories, and hospitals.

- Non-Slip Epoxy Flooring → Safe solutions for parking garages, ramps, and slippery surfaces.

- Chemical-Resistant Epoxy Flooring → Provides chemical protection for chemical plants, workshops, and petroleum facilities.

- Decorative Epoxy Coating → Aesthetic and durable flooring for showrooms, offices, and commercial spaces.

- Cold Storage Epoxy Coating → Resistant to deformation in low-temperature environments.

- Antistatic Epoxy Coating → Prevents electrostatic buildup in electronic manufacturing facilities and sensitive laboratories.

We offer custom epoxy flooring solutions for every industry and requirement!

Advantages of Epoxy Industrial Flooring

- High Durability → Long-lasting performance against heavy loads, forklift traffic, and abrasion.

- Chemical Resistance → Superior protection against acids, oils, solvents, and other chemicals.

- Non-Slip & Safe → Textured surface options to prevent slipping and ensure safety.

- Antibacterial & Hygienic → Easy to clean, stain-resistant surface for a sanitary environment.

- Aesthetic Appearance → Offers decorative solutions with a wide range of colors and patterns.

- Fast Application & Short Curing Time → Minimizes operational downtime.

- Water & Moisture Resistance → Waterproof surface ensures long-term durability.

At Globsan, we provide high-quality epoxy flooring solutions for industrial applications!

Epoxy Industrial Flooring Installation Process

At Globsan, our on-site teams utilize professional application techniques to ensure that epoxy flooring is durable, long-lasting, and safe.

Site Inspection & Surface Analysis

- Measurements of the area to be coated are taken, and the surface condition is assessed.

- Surface irregularities, cracks, and moisture levels are identified.

- The most suitable epoxy flooring type is selected based on usage needs.

Proper surface preparation is the foundation of a successful epoxy flooring application.

Surface Preparation & Primer Application

- The surface is cleaned of oil, dust, and dirt.

- Cracks, holes, and surface defects are repaired using special epoxy filler.

- A primer (epoxy-based) is applied to the concrete surface to create a strong bond between the floor and coating.

The primer application ensures excellent adhesion of the epoxy to the surface.

Epoxy-Based Intermediate Layer Application

- An epoxy intermediate layer is applied to increase impact resistance and load capacity.

- This layer enhances the floor thickness, ensuring a long-lasting and durable structure.

- During the curing period, the surface is protected, and no traffic is allowed.

The intermediate layer strengthens the epoxy flooring and enhances wear resistance.

Final Epoxy Layer & Colored Coating Application

- The topcoat epoxy layer creates a smooth and aesthetically pleasing surface.

- The coating can be applied in desired colors and patterns.

- If a non-slip surface is required, a textured epoxy coating is preferred.

Epoxy coating provides a stylish and durable finish to the flooring.

Line Marking & Signage (Optional)

- Directional and safety lines are applied in warehouses, parking areas, and factories.

- Pedestrian walkways, vehicle routes, and emergency exits are marked using epoxy-based paints.

Floor markings enhance safety and help organize traffic flow in industrial areas.

Final Inspection & Project Handover

- The epoxy coating is allowed to cure for the designated time.

- The surface is inspected, and durability tests are performed.

- Once final adjustments are made, the flooring is ready for use.

At Globsan, we ensure the flawless application of epoxy flooring with high-quality craftsmanship and

professional finishing!

Epoxy Industrial Flooring Applications & Usage Areas

- Factories & Production Facilities → Durable flooring resistant to heavy traffic and chemicals.

- Logistics & Warehouses → Abrasion-resistant coating suitable for forklift and pallet traffic.

- Food Processing Facilities → Hygienic, antibacterial, and stain-resistant flooring.

- Hospitals & Laboratories → Antistatic and chemically resistant flooring solutions.

- Parking Garages & Workshops → Non-slip epoxy coatings resistant to oil and water.

- Petrochemical & Chemical Industries → Special epoxy coating with high acid and solvent resistance.

- Commercial Spaces & Showrooms → Aesthetic and long-lasting flooring solutions.

At Globsan, we provide the most suitable epoxy industrial flooring solutions tailored to your needs!

Professional Epoxy Flooring Solutions with Globsan!

- Durable and aesthetic epoxy coatings for factories, warehouses, parking areas, and commercial spaces.

- High-quality materials, expert craftsmanship, and guaranteed applications.

- Fast installation, long-lasting durability, and low-maintenance flooring solutions.

- Chemically resistant, abrasion-proof, and hygienic epoxy flooring solutions.

Contact us today, and let’s bring your professional epoxy industrial flooring projects to life!