EPDM Poured Flooring – Tartan Flooring Construction

EPDM (Ethylene Propylene Diene Monomer) flooring is one of the most preferred flooring solutions for sports fields, playgrounds, walking paths, and public areas, thanks to its high durability, flexibility, and non-slip surface. Its superior resistance to abrasion and weather conditions ensures long-lasting use.

At Globsan, we offer professional solutions for EPDM flooring applications, creating safe, aesthetic, and durable surfaces for all areas, from sports fields to playgrounds.

Advantages of EPDM Flooring

1. Long-Lasting and Durable

- Suitable for heavy use and resistant to wear.

- Ideal for outdoor areas and sports fields, ensuring years of flawless performance.

- Resistant to chemicals and environmental impacts, with colors that do not fade.

2. Shock-Absorbing and Flexible

- Provides a safe surface for athletes and children.

- Softens falls and impacts, minimizing the risk of injury.

- Ideal for playgrounds, schoolyards, and sports fields.

3. Weather Resistance

- Withstands extreme heat and cold conditions.

- Unaffected by sunlight, ensuring no color fading.

- The permeable surface quickly drains rainwater, preventing water accumulation.

4. Aesthetic and Functional

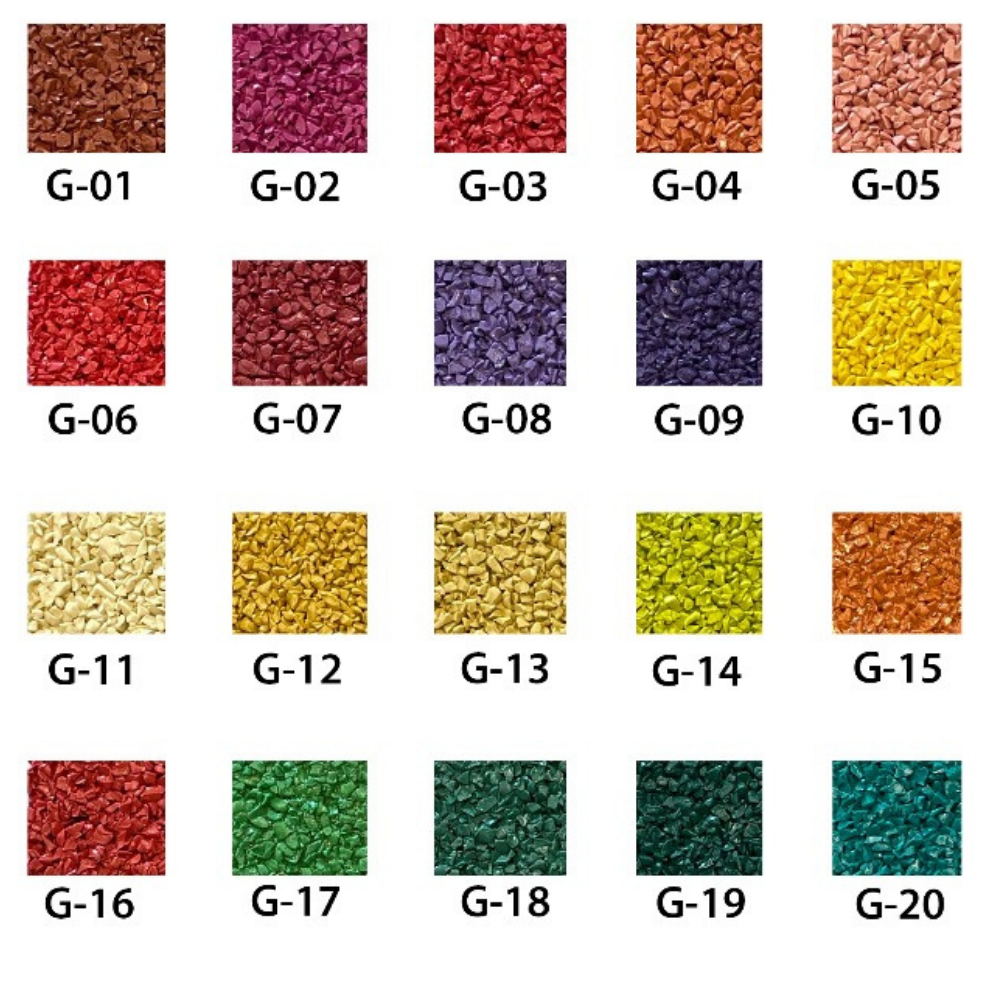

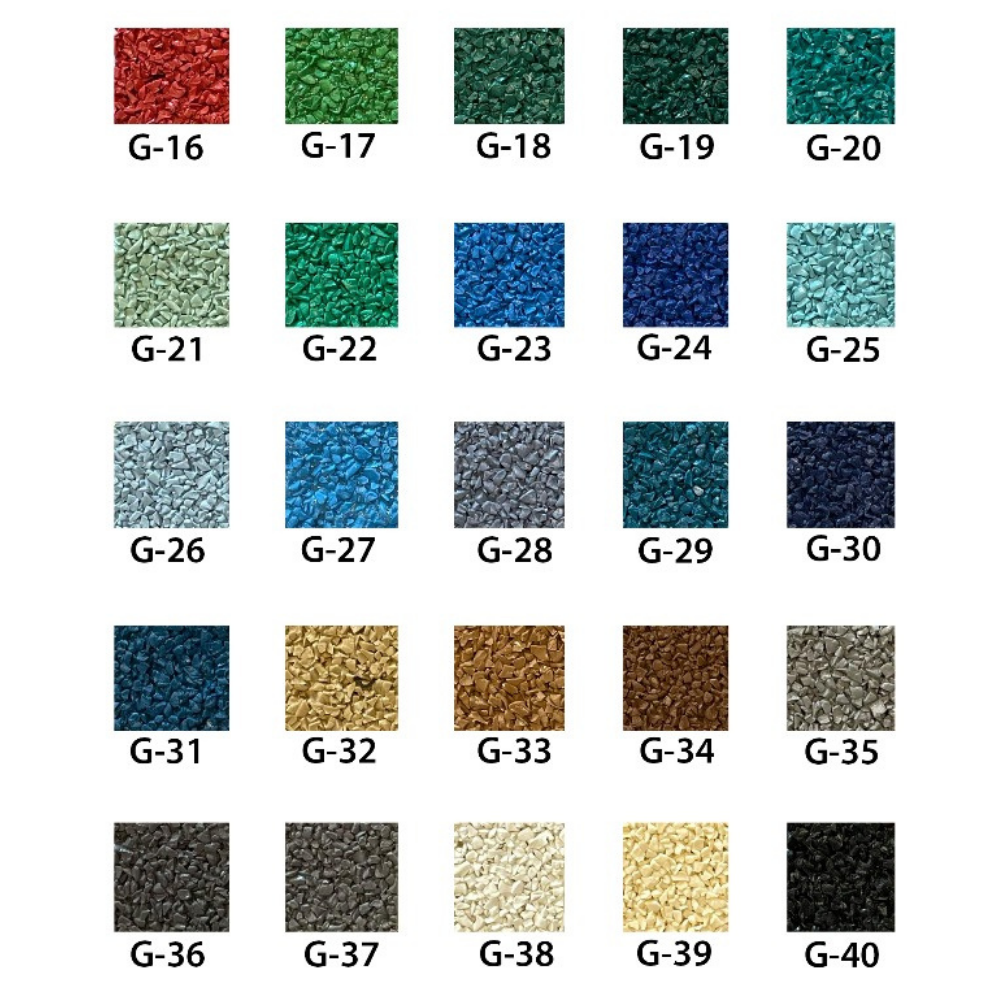

- Enhances spaces with vibrant color options.

- Educational patterns can be applied in playgrounds, while custom game lines can be added to sports fields.

- Ideal for decorative applications that complement urban landscapes.

5. Easy Maintenance and Cleaning

- EPDM floors require low maintenance.

- Regular sweeping and washing with water ensure long-lasting use.

- No need for special cleaning chemicals.

EPDM Flooring Application Areas

Sports Fields and Athletics Tracks

- Non-slip and shock-absorbing surfaces for basketball, tennis, volleyball, and football fields.

- Specially designed for athletics tracks to help athletes maintain their speed.

- Shock-absorbing structure that protects athletes’ joint and muscle health.

Children’s Playgrounds and Parks

- Soft and safe surface to protect children from falls.

- Colorful designs with educational and fun figures.

- Made from non-toxic, anti-carcinogenic materials, ensuring child safety.

Ship Decks and Yacht Flooring

- Non-slip and durable surface suitable for marine environments.

- Special EPDM coating options to prevent falls and slips.

- Resistant to saltwater and UV rays.

Walking and Running Paths

- Elastic surface specially designed for comfortable walking and exercise.

- Safe use with non-slip and shock-absorbing properties.

- Permeable surface technology for water drainage.

School Yards and Kindergartens

- Provides a comfortable and safe play area for students.

- Colorful surfaces attract children’s attention and add vibrancy to play areas.

- Easy-to-clean and durable structure ensures safe use for many years.

Public Spaces and Accessible Pathways

- Specially designed accessible flooring solutions for wheelchair users and individuals with disabilities.

- Ensures safe use in public buildings, parks, and recreational areas.

How is EPDM Flooring Applied?

EPDM (Ethylene Propylene Diene Monomer) flooring is preferred as a long-lasting and safe flooring solution in various areas such as sports fields, playgrounds, walking paths, ship decks, and marina piers. Its durability, non-slip surface, and flexible structure provide impact protection while offering an aesthetic appearance.

When applied following the correct steps, EPDM flooring creates a durable surface that lasts for years. At Globsan, our experienced field teams provide customized solutions for each project, delivering long-lasting floors with the best application techniques.

EPDM Flooring Application Process

1. Surface Preparation

- The surface is cleaned and cleared of dust, dirt, and moisture.

- The smoothness of the existing surface is checked, and slopes are adjusted to prevent water accumulation.

- Necessary corrections are made on different surfaces such as asphalt, concrete, or ship decks.

For maritime applications:

- Rust and wear are removed from ship decks and yacht flooring.

- Special marine primers are applied to prepare the surface for EPDM coating.

2. Primer Application (Bonding Layer)

- A special primer is applied to the surface to ensure strong adhesion of the EPDM coating.

- The layer, consisting of an ethyl acetate and polyurethane binder mixture, ensures the longevity of the coating.

- Once the primer is fully dry, the next step begins.

Using primer enhances the adhesion of the EPDM coating to the surface, extending its lifespan and improving durability.

3. SBR Granule Base Layer Application (Shock-Absorbing Layer)

- An 8 mm thick layer of SBR (Styrene-Butadiene Rubber) granules is applied to the surface.

- The granules are mixed with 18% polyurethane binder and compacted using a trowel.

- This layer is typically black and provides shock absorption.

- It requires approximately 10-15 hours to dry, during which the surface should not be walked on.

The SBR layer forms a flexible, impact-absorbing base for the EPDM coating.

4. EPDM Granule Top Layer Application

- Colored EPDM granules, sized 1-3 mm, are mixed with 20% polyurethane binder.

- Applied in a 5 mm thick layer, it is spread evenly over the SBR base and leveled with a trowel.

- This layer can be applied in various colors to create decorative and functional designs.

- Drying takes approximately 24-36 hours, and the surface should not be accessed during this period.

At this stage, unique designs can be created with different patterns and color combinations. Educational patterns for playgrounds, game lines for sports fields, and non-slip surfaces for ship decks can be applied.

5. Line Painting and Final Checks

- For sports fields, special polyurethane-based line paints are used to mark game boundaries.

- Quality checks are performed to inspect all sections of the flooring.

- The EPDM coating requires approximately 72 hours for complete curing.

This final stage ensures that the area is fully prepared for use and that all necessary inspections are completed.

EPDM Flooring Standards

- EN 933-1 → Measures the amount of dust particles.

- EN 1097-3 → Determines the density of filler materials.

- EN 71-3 → Complies with toy safety standards.

- FIFA Test Method 11 (TGA) → Includes suitability tests for sports fields.

Globsan EPDM flooring is produced using certified, health-safe materials that meet international quality standards. Our products provide safe, long-lasting, and durable surfaces for sports fields, parks, walkways, and playgrounds. We ensure high-quality materials, expert craftsmanship, and guaranteed applications.

Safe and Professional Applications with Our Field Teams

At Globsan, every stage of EPDM flooring installation is handled by our experienced field teams. Our experts, specializing in both land and marine projects, deliver top-quality services, ensuring that each floor is durable, safe, and aesthetically pleasing.

Our field teams:

- Consist of certified professionals with expertise and experience.

- Specialize in marine-grade EPDM applications, resistant to saltwater and humid environments.

- Provide tailored solutions for sports fields, walkways, ship decks, and marinas.

- Prepare for each project with a customized approach, ensuring timely delivery with high quality.

- Conduct post-installation quality checks to guarantee long-term customer satisfaction.

Why Choose Globsan EPDM Flooring?

- Shock-absorbing and flexible structure → Provides a safe surface for children and athletes.

- Non-slip surface → Ensures high grip in wet and dry conditions.

- UV and weather-resistant → Does not fade or crack for years.

- Wide range of colors and patterns → Offers various design options.

- Water permeability and quick drying → Prevents water accumulation and reduces slipping risk.

- Low maintenance cost → Easy to clean and maintains durability for years.

At Globsan, we apply EPDM flooring with the highest standards in durability, safety, and aesthetics.

Contact Us for More Information

With expert field teams for land and marine projects, we deliver the most durable and safest EPDM flooring applications.